(PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING

Purpose The article reports a wet milling process, where the planetary ball mill was combined with pearl milling technology to reach nanosize range of meloxicam (Mel; 100500 nm).

WhatsApp)

WhatsApp)

Purpose The article reports a wet milling process, where the planetary ball mill was combined with pearl milling technology to reach nanosize range of meloxicam (Mel; 100500 nm).

Process Engineering Of Size Reduction Ball Milling Aime. Process Engineering of Size Reduction Ball milling Volume 1 Leonard G Austin Pennsylvania State University 1981 Ball mills 0 Reviews What people are saying Write a review We havent found any reviews in the usual places Bibliographic information Title Process Engineering of Size Reduction Ball milling Volume 1 Author Leonard

Process Engineering of Size Reduction: Ball Milling by Austin, Linda Gong at ISBN 10: ISBN 13: Society for Mining Metallurgy 1984 Hardcover

Subject(s): Ball mills; Grinding machines; Size reduction of materials; ISBN: Bibliography Note: Includes bibliographical references and index.

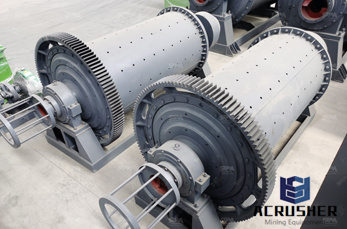

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many

Process engineering of size reduction : ball milling.. [L G Austin; R R Klimpel; P T Luckie] Home. WorldCat Home About WorldCat Help. Search. Search for Library Items Search for Lists Search for Contacts Search for a Library. Create

Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has

#0183;#32; GuptaThe effect of particle size distribution on grinding rate in dry ball milling, Laval university, Quebec, Canada, for presentation at the SMEAIME annual meeting, Denver, Colorado (1987), pp.

Cone milling is one of the most common methods of milling in the pharmaceutical, food, chemical and associated industries. They are typically used for size reduction and deagglomeration or delumping of powders and granules.. Generally used for reducing material to a particle size as low as 180#181;m (80 mesh) they produce less dust and heat than alternative forms of milling.

Process Engineering Of Size Reduction Ball Milling L G. Process Engineering of Size Reduction Ball Milling Authors L G Austin R R Klimpel P T Luckie Edition illustrated Publisher Society of Mining Engineers of the AIME 1984 ISBN. Read More. Size Reduction Of Material Using Ball Mill Labmonk

Size reduction by crushing has a size lim itation for the final products. If we requir e further reduction, say below 520 mm, we have to use the processes of grinding.

Process Engineering of Size Reduction: Ball Milling L. G. Austin, R. R. Klimpel, P. T. Luckie Society of Mining Engineers of the AIME, 1984 Ball mills 561 pages

This process is experimental and the keywords may be updated as the learning algorithm improves. This is R. R. Klimpel, and P. T. Luckie, The Process Engineering of Size Reduction: Ball Milling, AIME, New York, 561 p (1984). Google Scholar Size Reduction of Coal, in AIME Handbook, Coal Preparation, Harvey Mudd Series, edited by J

7 #0183;#32;Process Engineering of Size Reduction: Ball Milling L. G. Austin, R. R. Klimpel, P. T.

Process Engineering Of Size Reduction book. Read reviews from worlds largest community for readers. Process Engineering Of Size Reduction: Ball Milling by. Klimpel. #183; Rating details #183; 2 ratings #183; 0 reviews Get A Copy. Amazon;

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Get this from a library! Process engineering of size reduction : ball milling. [L G Austin; R R Klimpel; P T Luckie]

The analysis of size reduction in tumbling process engineering of milling circuits is intimately linked with the kinetic. process engineering scope of work That describe the size reduction process in a perfectly mixed ball mill can process of mechanical alloying using ball milling transfers mechanical.

#0183;#32;Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: ''Ball milling is a method used to break down the solids to smaller sizes or into a powder. A

Stage 1. The material is introduced into the mill via the primary air feed where the material is mixed with air, thereby minimizing the risk of agglomeration. Stage 2. The material enters the grinding chamber where grinding takes place in the same way as a conventional rotary impact mill.

WhatsApp)

WhatsApp)