india ball mill for continuous grinding

Continuous Ball Mill, Manufacturer, IndiaIt is a kind of grinder, used to ground different types of materials like chemicals, ceramic material, paint or etc. Fo india ball mill for continuous grinding

WhatsApp)

WhatsApp)

Continuous Ball Mill, Manufacturer, IndiaIt is a kind of grinder, used to ground different types of materials like chemicals, ceramic material, paint or etc. Fo india ball mill for continuous grinding

Continuous Rod and Ball MillSepor, Inc. Sepors 16 x 32 continuous ball or rod mill is ideal for pilot plant studies of ore grinding and processing or just regular small scale grinding requirements you may have. The mill can be used in a closed circuit, with a spiral classifier, screen or cyclones or as a single pass grinding price

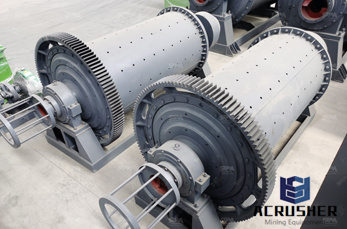

Ball mill rotates on its axis. Mill rotates on four roller and two tiers. It is provided with girth gear along with gear box and motor. Features of Continuous Ball Mill:Low installation cost; Low power consumption; Perforated grinding plates are provided for final product size. Dust proof chamber; Digital display; Steel balls are provided to the chamber.

Indian ball mill for continuous mill wikipedia the ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dressing of both

Ball MillCylindrical. Rs 3 Lakh/ Unit Get Latest Ball Millis an efficient tool forgrinding materialslike ores, chemicals, ceramic raw materials, paints etc. into fine powder or fine paste bygrindingin a wet way. TheBall Milloperates by rotating a cylinder withgrinding ballslike steel, CI, ceramic andpebble ballsasgrindingmedia.

Owing to our scheduled trade operations, we share forefront amid the leading continuous ball mill manufacturers in India. The Neoprene barrel inside the continuous ball mill contains the grinding media which is loaded with the material. This barrel rotates for many hours on a go and mixes and grinds the materials into powder.

According to the milling way, the Ball Mill can be divided into dry and wet types according to ways of discharge Ball mill is useful for both application grinding as well as mixing purpose Capacity Range: Up to 5000 ltr in batch type ball mill; Up to 10 TPH in continuous type ball mill Hardness: up to 9 mohs scale Application:

In the process of material grinding, the continuous ball mill adopts a continuous and uninterrupted form for feeding, grinding, and discharging. According to different operation process, ball grinding mill can be divided into continuous ball mill and batch ball feeding and discharging process of the continuous type ball mill is continuous, which can be produced in open or closed

High Energy Ball Mill Emax Revolutionizing Ultrafine Grinding Unlike other high energy ball mills the Emax is capable of continuous grinding operation without interruptions for cooling down. This dramatically reduces the. Ball Mills Manufacturers and Suppliers in India Find here Ball Mills manufacturers and OEM manufacturers India. Get

Continuous Ball Mill, Manufacturer, India. Sep 14, 2020 Continuous Ball Mill It is a cylindrical grinder having three different compartments and screen. Replaceable liners or balls are fixed inside entire mill. Balls are made of stainless steel, rubber and other metals with

WhatsApp)

WhatsApp)