Ball mill gear manufacturing

Ball mill gear manufacturing. Time: . The world''s energy is limited, but the development is wireless, with the increasingly rapid pace of development,

WhatsApp)

WhatsApp)

Ball mill gear manufacturing. Time: . The world''s energy is limited, but the development is wireless, with the increasingly rapid pace of development,

Gear, wheel The larger of two interacting gears or a gear on its own. Pinion The smaller of two interacting gears. Path of contact Path followed by the point of contact between two meshing gear teeth. Line of action, pressure line Line along which the force between two meshing gear teeth is directed. It has the same direction as the force vector.

Developed in 1966, our twostage planetary gear unit guarantees optimum power transmission and speed reduction for your ball mill. The standard for central driven ball mills in the cement industry today, our MAAG#174; GEAR CPU Gear Unit drives hundreds of raw and clinker ball mills all around the globe.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

The first part of the mill that we will look at is the TRUNNION BEARING. This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load. Usually it is constructed from Babbitts metal. If you happen to remember the introduction to this course Issac Babbitt was the man who devised the method of bonding selflubricating metals onto a strong backing to form a bearing

Planetary ball mills. A planetary ball mill consists of at least one grinding jar, which is arranged eccentrically on a socalled sun wheel. The direction of movement of the sun wheel is opposite to that of the grinding jars according to a fixed ratio. The grinding balls in the grinding jars are subjected to superimposed rotational movements.

Table of ContentsStructural Design of Mill and BearingsStructural Design of the BearingOperational ResultsMaintenance of Gearless Drive Mill The reliability of large diameter, high horsepower ball mill is paramount when large production and minimum downtime is required. The 17 ft. x 56 ft. double compartment ball mill at St. Lawrence Cement Company has the first gearless drive built in

#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

Table of ContentsStructural Design of Mill and BearingsStructural Design of the BearingOperational ResultsMaintenance of Gearless Drive Mill The reliability of large diameter, high horsepower ball mill is paramount when large production and minimum downtime is required. The 17 ft. x 56 ft. double compartment ball mill

Ball Mill Helical Gear Wheel Helical gears are one type of cylindrical gears with slanted tooth trace Compared to spur gears they have the larger contact ratio and excel in quietness and less vibration and able to transmit large force. Read the rest gt; Ball MillWikipedia.

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says quot;A ball mill is a type of grinder used to grind materials into extremely fine powder for use in

Jun 13, 2020 Learn to make involute Gear wheels! A cnc tutorial explaining the process of making a gear wheel on a hobby cnc router or mill.

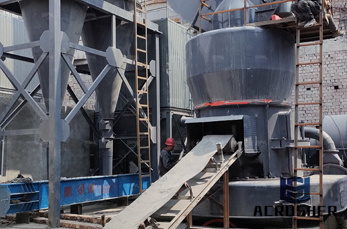

Girth gears (Gear wheels) are large ring gears which are normally fitted to the outside of ball mills or rotary kilns to provide the primary rotational drive,which is required to be operated in a long time So, the quality requirements during the actual production for the big gear ring are very high Girth gears are applied in the mining, cement, minerals industries used in various types of

table 1 ball mill shaft speeds, expected forcing amp; fault frequencies ball mills, forcing frequencies (cpm) shaft speeds 1x rpm motor speed 1,191 ball mill pinion speed 226 ball mill gear speed 18 gearbox (between motor amp; ball mill) nb ftf bsf 2x bsf bpfo bpfi input brgs, skf#22330 15

Bulkbuy 8m Diameter Large Girth Gear Used for Ball Mill price comparison, get China 8m Diameter Large Girth Gear Used for Ball Mill price comparison from Gear, 8m Diameter Gear manufacturers amp; suppliers on Video Channel of .

offers 329 ball mill gear wheel products. About 17% of these are spur gears. A wide variety of ball mill gear wheel options are available to you, such as steel, stainless steel, and iron.

offers 1,918 ball mill gear products. About 5% of these are Spur Gears, 0% are Worm Gears, and 1% are Bevel Gears. A wide variety of ball mill gear options are available to you, such as warranty of core components, material, and local service location.

WhatsApp)

WhatsApp)