Wet Grinding in Planetary Ball Mills RETSCH YouTube

#0183;#32;Planetary Ball Mills are used wherever the highest degree of fineness is required. QUOTE REQUEST amp; MORE INFORMATION: In addition

WhatsApp)

WhatsApp)

#0183;#32;Planetary Ball Mills are used wherever the highest degree of fineness is required. QUOTE REQUEST amp; MORE INFORMATION: In addition

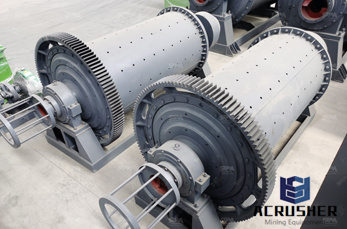

Wet ball mills Ball mill is widely used in mining, smelting,road,building material and chemical. It is the key equipment for grinding after the crush mill consists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unit.

Every mining operation has a unique grinding process. Variable needs require versatile grinding equipment. offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needs.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

Gold Extraction Equipment. Carbon Screen; Washing Thickener; Air Lifter; Leaching Agitation Tank; Zinc Powder Displacement Device Contact; Home; Products; mixing wet ball mill machine for best quality; mixing wet ball mill machine for best quality. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic

Ball milling of graphite with appropriate stabilizers is another mode of exfoliation in liquid phase. 21 Graphite is ground under high sheer rates with millimetersized metal balls causing exfoliation to graphene (Fig. ), under wet or dry instance, this method can be employed to produce nearly 50 g of graphene in the absence of any oxidant. 22 Graphite (50 g) was ground in

While the wet milling process is capital intensive with higher operating costs, the ability to produce a variety of products can be valuable in dealing with volatile markets. The wet milling process results in slightly lower ethanol yields than a traditional dry milling process since some of the fermentable starch exits the process attached to the saleable coproducts.

SAG Mill Circuit Example Gold Processing SAG mill circuit example for gold processing [image: (13563)] AG/SAG Mill. AG/SAG mills are normally used to grind runoffmine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Ball Mill Machine / Wet Pan Mill, Ball Mill, Wheel Mill for Gold 1000 Details manufacturer / supplier in China, offering Gold Wet Pan Mill Best Sell, High Quality Parafina Fr6466, Cheap White Paraffin Wax, Food Use and Coating Paraffin Wax 56 58 and so on.

Ball mill machine wet milling machine gold mill ball mill ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powdermaking production line including cement silicate newtype building material refractory material fertilizer ore dressing of ferrous metal and nonferrous metal glass ceramics etc and the.

21/08/2020#0183;#32;3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball mill. 4 The grinding particle size is fine and uniform, and the wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material and the plastic material well.

Gold Extraction Equipment. Carbon Screen; Washing Thickener; Air Lifter; Leaching Agitation Tank; Zinc Powder Displacement Device; Desorption Electrolysis System; Mineral Processing EPC; Solutions; About; Contact; Home; Products; wet ball mill in pelletisation; wet ball mill in pelletisation. Efficient Thickener. Efficient Thickener. Hydraulic

With more than 100 years of experience in ball mill technology, Metsos ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Ball Mill Wet Milling Gold. Wet Mill Youtube, May 17 2017 ball mill grinding machine wet ball mill dry 357 1200 sudan wet pan mill gold stone mill grinding gold ore machine gold the leader of corn wet milling industry in indonesia Ball Mill Wet Milling Gold.

21/05/2014#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

gold pan mill, gold milling machine, gold miller The wet pan mill, which is named by the diameter of grinding roller, is mainly applied for grinding rock gold ore. In Sudan, at least 85% gold miners are using the Gold Grinding Machine (wet pan mill) in their gold processing system.

The wet ball mill has two types as follow: grid type and overflow grain size limit of the grinding mill is usually ~, so it is commonly used in the first segment. The particle size of the grinding mill is generally less than, so it is suitable for the second grinding of the middle product in the twostage grinding process. The gridtype ball mill can discharge the qualified product in time, reduce the

China mining gold copper quartz limestone ore milling machine grinder grinding machine manufacturer supplier in china offering mining gold copper quartz limestone ore cement aluminium powder dry ball mill machine price energy mining applicable industries silica quartz sand wet ball mill long life gold copper slurry wet ball mill and so on.

WhatsApp)

WhatsApp)