(PDF) Effect of Milling Time on Particle Size and Surface

Ball milling is a top down approach and a method to reduce size of particle while Zeolite is a valuable inorganic materials having wide variety of applications.

WhatsApp)

WhatsApp)

Ball milling is a top down approach and a method to reduce size of particle while Zeolite is a valuable inorganic materials having wide variety of applications.

manufacture of nano zeolite natural zeolite using ball mill. manufacture of nano zeolite natural zeolite using ball mill. effect of milling time on particle size and surface, page 1. effect of milling time on particle size and surface morphology of commercial zeolite by planetary ball mill mukhtar 1,2,a, borhan1,2, m. rusop2zeolite

#0183;#32;Xray diffractometry, analysis, cationexchange capacity, and solubility were used to characterize the effect of ball milling on zeolite A, zeolite X, and synthetic of spectra during the ball milling show that a loss of crystallinity, a decrease of cationexchange capacity, and an increase of solubility were caused by breaking of Si O Si and Si O Al bonds in the

#0183;#32;Wet ball milling, as a potential means to decrease the particle size of zeolite HY with minimal loss of crystallinity, was investigated. The diameter of the ball as well as the milling speed and time were varied in the experiments.

Characterization of Moganite Obtained From Natural Zeolite By Ball Milling. January 2018; 2014, 115123. [13]. Y. P Type of amorphization induced by ball milling was defined on the basis

#0183;#32;Ball milling of clinoptilolite zeolite was performed by mean of a planetary ball mill (PM100; Retsch Corporation). To optimize the milling conditions with respect to size reduction and crystallinity retention, milling parameters such as rotational speed, ball to powder and water to powder ratios as well as, grinding time were varied for different experiments.

Ball milling is a top down approach and a method to reduce size of particle while Zeolite is a valuable inorganic materials having wide variety of applications. In this paper, ball milling of commercial synthetic Zeolite powder was studied with their time varied. Wet ball milling was selected as a potential means to decrease the particle size of Zeolite over dry grinding.

Wet ball milling, as a potential means to decrease the particle size of zeolite HY with minimal loss of crystallinity, was investigated. The diameter of the ball as well as the milling speed and

#0183;#32;Fig. 1. shows the schematic diagram and mechanism of milling of sample powders using a planetary ball mill. Fig. 1. Schematic diagram of milling of Zeolite 4A powders in the planetary ball mill Various milling parameters like balls to powder ratio, milling duration, size of milling media influence the effective grounding of powders.

To achieve this objective, initially, the zeolite particle size was reduced to 23 m by wet ball milling, and during this process the crystallinity and surface area of the powder were not significantly affected. The rheological behavior of the zeolite slurries is a function of the type of zeolite and solid content.

#0183;#32;Wet ball milling of microsize HY zeolites has been systematically studied at a wide range of speed, time, and different ball sizes using a high energy ball mill. The milling process of this material produced three types of species namely nanoparticles, flakes/slabs, and unground microsize zeolite.

Wet ball milling of zeolite HY Request PDF. Wet ball milling as a potential means to decrease the particle size of zeolite HY with minimal loss of crystallinity was investigated. The diameter of the ball as well as the milling speed and . Get Price; Optimized experimental design for natural clinoptilolite .

Subsequently the zeolite sample were milled by ball milling (Retsch PM 100 Planetary Mill). The aim was to obtain moganite, a type of microcrystalline silica mineral.

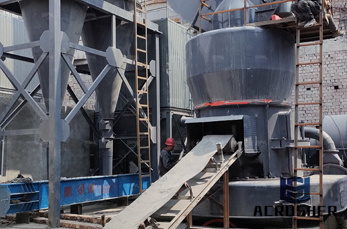

zeolite ball milling. Grinding Zeolite Ball Mill Machinetembaletu. Industrial zeolite grinding mill parsana. grinding zeolite ball mill machine YouTube. 8 Jan 2014 screen grinding mill mobile crusher cone crusher etc for quarry micronized mineral zeolite manufacturer mill 10 Jul 2013 micronized mineral zeolite manufacturer mill we provide cone

mean size about mm. Ball milling Zeolite 4A was performed by means of a planetary ball mill (Fritsch of Pulvertizer5). A certain amount (25 gm) of Zeolite sample was ground for 12 hr in

The impact forces of the balls are weaker duringBall Mill Loading, Ball Mill Loading Dry Milling #183; 50% media charge #183; Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize mediaBall mill, Grinding machine, Wet ball mill, Dry ball, 21 May 2014 Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for

WhatsApp)

WhatsApp)