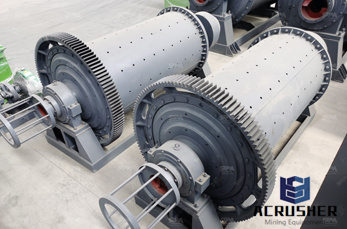

mining equipment ball mill, mining equipment ball mill

offers 2,256 mining equipment ball mill products. A wide variety of mining equipment ball mill options are available to you, such as condition, local service location, and applicable industries.

WhatsApp)

WhatsApp)

offers 2,256 mining equipment ball mill products. A wide variety of mining equipment ball mill options are available to you, such as condition, local service location, and applicable industries.

VIBRADRUM#174; Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven energy savings range from 35 to 50% reductions in kW hours per ton of processed material. 5 to 10 times longer media life.

Energy Saving Mining Ball Mill. Visit Us. Welcome you visit our factory when you feel free . About Us. Solutions. 08 Dec 2020. Slag Grinding. December 8, 2020. Slag is a common raw materials for cement industry. The hardness of slag is around 67 in Mohs scale (harder than cement clinker). For the aim to grind slag (1520 mm) to a final

Ball mill for mine. Ball Mill is a key mineral processing equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, benefication plant.

Inventory ID: 6CHM01. 3 Units UNUSED FL 26 x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

Placer mining and lode mining are very different. One of such equipment is the ball mill. Below is the writeup of how a ball mill works, For the center unloading mills, the ground material is discharged through a hollow unloading trunnion using a free sink.

DOVE Ball Mills are highly efficient size reduction machines, designed for grinding applications, where fine material is required. Applicable for wet and dry grinding applications within the following branches of industries: Mining, Hard Rock (primary deposit) Gold Mining Application, as

The ball mill has strong adaptability to materials and is suitable for grinding hard materials, such as aluminum ash, lime, slag, molybdenum ore, etc. 2. According to Granularity Properties. Rod mill adopts high carbon steel rod with carbon content of % 1% and diameter of 50100 mm as grinding medium.

#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

Liner and grinding medium of ball mill. liners and grinding media are important components of ball mills or indispensable for work, they are easy to wear and consume a lot. 1) Liners of ball mill. Liner material can be made of hard chromium steel, high manganese

Ball mill is a kind of grinding mill used in the mineral processing, which is to further grinding the material fitness to the appropriate particle size that meets the industrial requirement after the crushing process. At present, the ball mill machine is widely used in mine, cement, silicate products, building materials and other fields. 1. Structure of ball mill

The latest Ball Mill (Mining) market research added by Market Study Report, LLC, delivers a concise outline regarding the potential factors likely to drive the revenue growth of this industry. The report delivers valuable insights on market revenue, SWOT Analysis, market share, profit estimation and regional landscape of this business vertical.

Energy Saving Mining Ball Mill. Visit Us. Welcome you visit our factory when you feel free . About Us. Solutions. 08 Dec 2020. Slag Grinding. December 8, 2020. Slag is a common raw materials for cement industry. The hardness of slag is around 67 in Mohs scale (harder than cement clinker). For the aim to grind slag (1520 mm)

The ball mill is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size. Main ball mill components: cylinder, motor drive, grinding medium, shaft.

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

Jun 14, 2018#0183;#32;Below is the writeup of how a ball mill works, is used to crush ore and an explanation regarding its effectiveness in gold mining. The Purpose of Milling First of all, in order to get the best out of how this particular equipment is used it is important to get acquainted with knowledge on what it

Nov 26, 2019#0183;#32;The ball mill can be applied in the cement production plants, mineral processing plants and where the fine grinding of raw material is required. From the volume, the ball mill divide into industrial ball mill and laboratory use the small ball mill, sample grinding test.

Mar 31, 2018#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

#0183;#32;Grinding balls for mining usually adopt wet grinding ball mills, mostly manganese, steel, lead balls. Ceramic balls for ball mill often seen in the laboratory. Types of ball mill: wet grinding ball mill, dry grinding ball mill, horizontal ball mill, vibration mill, large ball

Cement Ball Mill. Cement in powder form can be changed from plasticity paste to hard stonelike body and can become a total cemented granular materials through physical and chemical processes after being mixed with water. So cement is a good mineral binder. Cement Introduction Of Cement Ball Mill:

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

WhatsApp)

WhatsApp)