AMIT 135: Lesson 7 Ball Mills amp; Circuits Mining Mill

Diagram of ball mill and interior cut away [image: (13572)] Ball Mill Design Parameters. Size rated as diameter x length. Feed System. One hopper feed; Diameter 40 100 cm at 30 #176; to 60

WhatsApp)

WhatsApp)

Diagram of ball mill and interior cut away [image: (13572)] Ball Mill Design Parameters. Size rated as diameter x length. Feed System. One hopper feed; Diameter 40 100 cm at 30 #176; to 60

BALL MILL DRIVES, LOADED, WAVEFORM LEVELS, SEPTEMBER 1A 1B Above is a plot of the waveform vibration levels at both the 1A amp; 1B ball mills when loaded (acceleration). Note how waveform levels at 1A ball mill are higher than that at 1B ball mill for every measurement and especially at points PIH PIA (pillow block, couplingend bearing).

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

ball mill diagram with vibrator. Adopting many advantages from various mills, and the ideal substitute of the traditional mill. Find out More of this Equiment. Read more. schematic diagram ball mill working.

Ball mill can be divided into ball roller . ball mill diagram with vibrator; ball mill diagram. ball mill manufacturers in jaipur; ball mill manufacturers in . . Jaipur Jalapa Jalisco Jam. Jamaica Jamaica rum Jamaica shorts James James Bay James I James II James VI Jamesian Jameson Jazenithwn Jammu and Kashmir Jamshedpur .

The vector stencils library quot;Industrial equipmentquot; contains 81 symbols of pumps, compressors, fans, turbines, and power generators. Use these shapes to design pumping systems, air and fluid compression systems, and industrial process diagrams in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of

Vibration mills are similar to ball mills in that particles of the materials are crushed between porcelain or metal balls and the mill body. Drugs and excipients are readily ground to less than 5 mm, the grinding time being considerably less than is required in normal ball milling.

Spain ball mill mining mineral is popular. cone crusher symbol flow sheet diagram youtube. ball mill trammel vibrator screen; gold ore mining equipment; ball mill for studio use; mills aluguel; cone crusher flow sheet diagram Crusher South Africa. cone crusher symbol flow sheet diagram cement plant coal mill grinding flow

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a

offers 834 ball mill diagram products. About 0% of these are Inverters amp; Converters. A wide variety of ball mill diagram options are available to you, such as applicable industries, output type, and aftersales service provided.

#0183;#32;Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill.

Vibrolator #174; ABU Ball Vibrator Like all our ball vibrators, this pneumatic vibrator is ideal for knocking down material blockages and is built for the toughest conditions. Patented by Martin Engineering, Vibrolator #174; vibrators are the original ball vibrators and still provide a

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a

Search in B#252;hler Group catalogs and technical brochures on DirectIndustry and find the information you need in 1 click.

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding

ball mill diagram with vibrator. Tribologie ABC. Tribology glossary index Listen to pronunciation. Get Price; Model T Ford Forum: Forum 2017 mtfca

The mixer mill MM 400 is a compact versatile benchtop unit, which has been developed specially for dry, wet and cryogenic grinding of small amounts of sample. It can mix and homogenize powders and suspensions in only a few seconds. It is also perfectly suitable for the disruption of biological cells as well as for DNA/RNA and protein extraction. With its high performance and great flexibility

#0183;#32;Vibration mills are similar to ball mills in that particles of the materials are crushed between porcelain or metal balls and the mill body. Drugs and excipients are readily ground to less than 5 mm, the grinding time being considerably less than is required in normal ball milling.

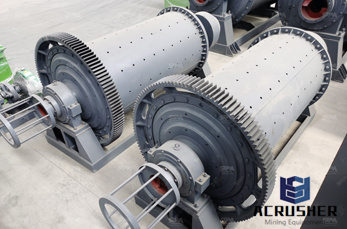

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

WhatsApp)

WhatsApp)